Hinge Redesign

The hinge as used for several prototype iterations has performed very well, with a tight fit without excess friction. However, as motor actuation gets closer, its clear that this hinge is not ideal.

The previous acutation method involved attaching wires to the body of the finger sections. However, as this is offset from the axis of movement the lengs of eahcocntrol string will inevitably not be constant while moving. To solve this issue there are two possibilties.

- Add springs to the actuators. By using springs on the actuating arms, this slight change in length can be absorbed. As well as adding a conformal element to each joint mechanically. THe problem in this is the potential lack of acuracy thanks to the conformal nature of the springs, and the control difficulties these add.

- Moving the control to be in line with the axis. By moving the point where the actuator wires connect to be inline with the axis of movement, this offset is removed and the control is simplified. The problem with this is the added complexity to the design, and the potential redesign of hinge and finger elements

It has been decided, after experimentation and design attempts, to move the axis inline. It is thought to be the easiest and most reliable of overcoming this issue.

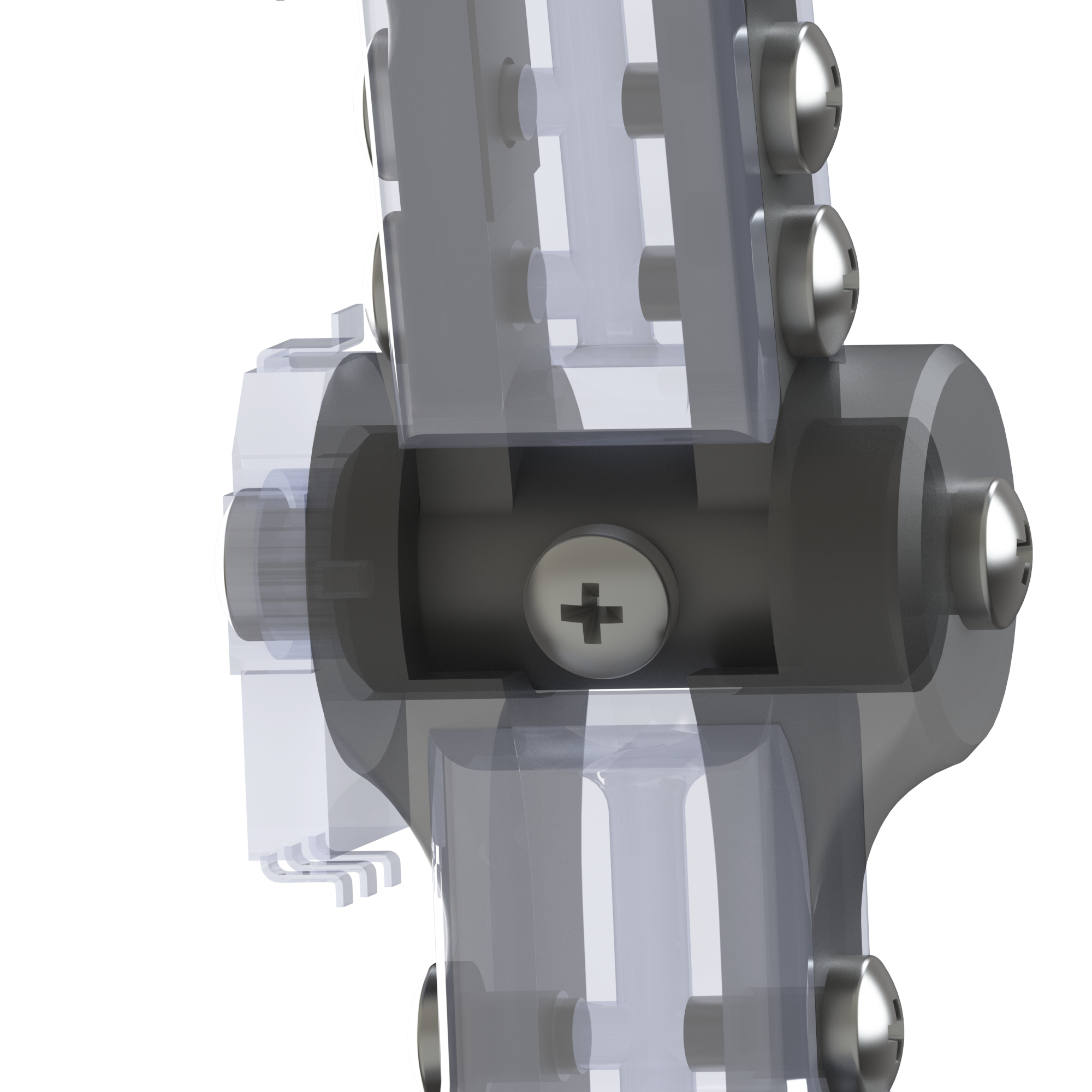

This design changes the interal element of the higne to be one single part and to ahve mounting points within that part so the actuation can be done along the axis.