Finger Prototype Five

Due to the iterative design process, the CAD models for the finger had become overly complex and difficult to work with.

Measuring joint angles

A new joint has been designed to fit surface mount potentiometers as mentioned in the sensor blog post. The potentiometer is in line with the hinge to measure the angle of the part.

Testing the 2SMPP-02 Pressure Sensor

Testbed

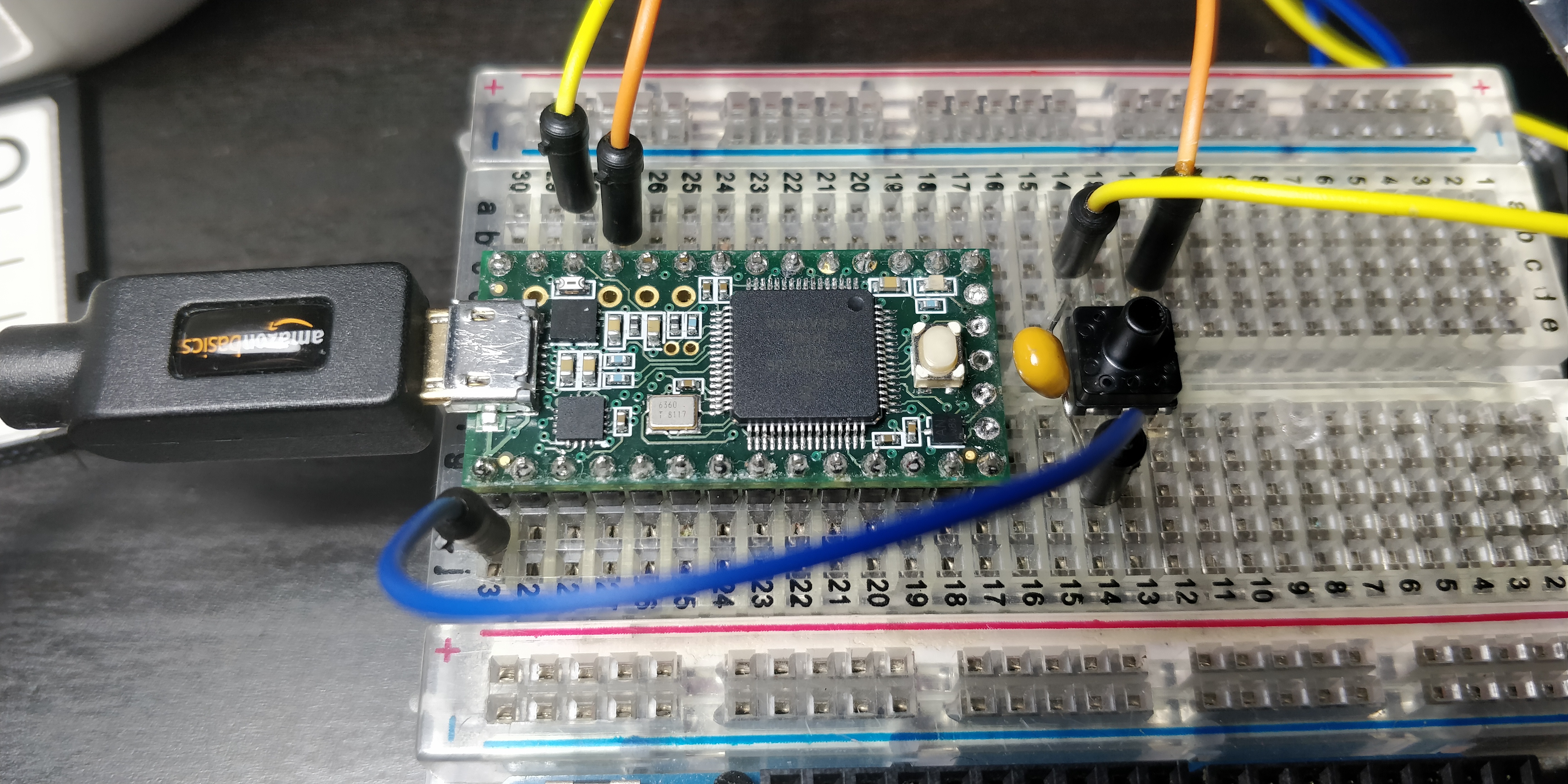

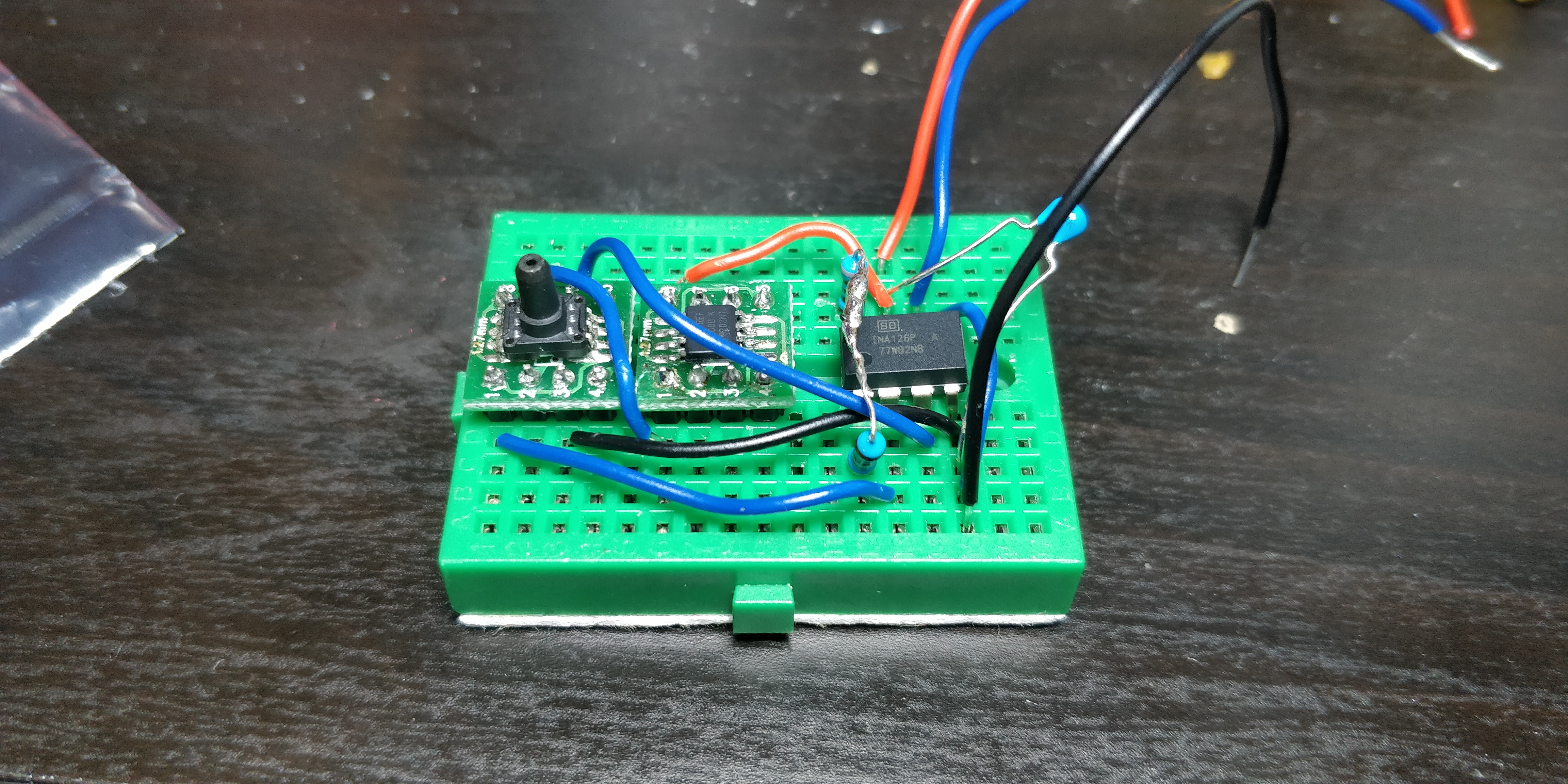

This sensor requires supprot circuitry to function correctly. Here, a cosntant current supply of 100uA from a REF2000AU supplies the sensor, then the output from the sensor is then amplified using an INA126PA Instrumentation Amplifier. This amplified signal is then fed into the ADC of a Teensy 3.2 Microcontroller

Methodology

Similar to the previous sensor, the pressure is applied using a human finger pushing on the nozzle of the sensor.

Results

Sadly, this test was a failure. The voltage output stayed constant a 3.5V, while the reason for this is unclear it does show the dificuilty of implementing this sensor comapried the the previous example.

Conclusion

It is unlikely this sensor will be used, not jsut because this test was a failure, but also the support circuitry required counters the advantage of a smaller sized sensor. The accuracy of such a sensor could not be established.

Testing the ADP51A11 Pressure sensor

Testbed

The sensor was mounted on a breadboard, powered by 3.3v and the analog output delivered to the ADC of a Teensy 3.2 with a 10uF capacitor filtering the power rail.